Biodegradable Plastics vs Corflute® and Polypropylene

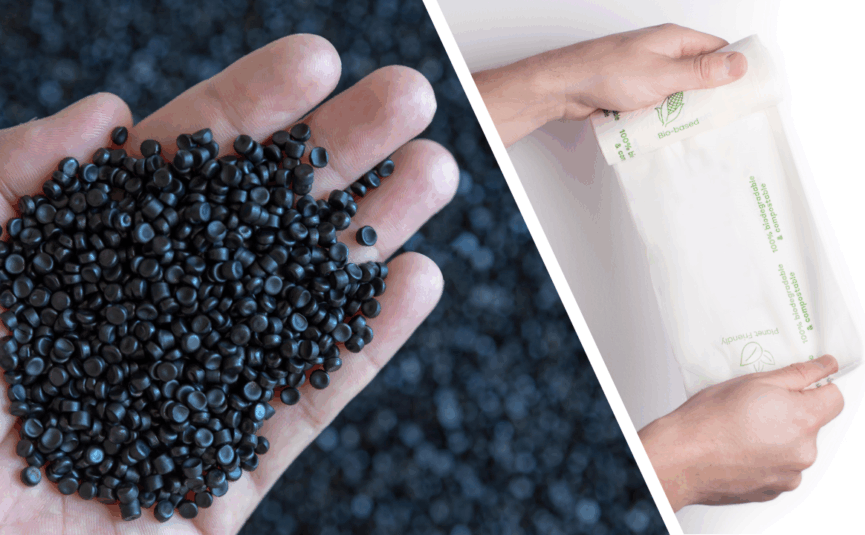

At first glance, the term “biodegradable material” sounds like the gold standard of sustainability. After all, who wouldn’t want a product that naturally breaks down over time? But when we look a little deeper, the story isn’t so simple. While biodegradable materials may appear eco-friendly, current commercially available biodegradable plastics only break down under specific industrial conditions, and they can’t be recycled through standard systems making them less effective for real-world applications, especially when compared to durable, fully recyclable materials like PROMEG® polypropylene (PP) and Corflute® (corrugated polypropylene).

Let’s break down the facts

The Hidden Truth About Biodegradables

- Many biodegradable plastics only break down under specific industrial composting conditions (conditions not available in most communities). Without these facilities, they end up in general waste or landfill, where they behave much like conventional plastics.

- Biodegradable materials cannot be recycled through standard recycling systems, which means every item is a single-use product destined for disposal.

Why Promeg® Polypropylene and Corflute® Stand Out

100% Recyclable & Reusable

Polypropylene can be recycled and reused multiple times, reducing the demand for new raw materials. This means less landfill waste and a smaller environmental footprint. Corflute, being made from PP, shares the same advantage, feeding into a true closed-loop recycling system.

Weather-Resistant and Long-Lasting

Cardboard and many biodegradable options degrade quickly when exposed to rain, wind, and sun. They absorb moisture, warp, and lose print quality fast.

- Polypropylene and Corflute remain strong and intact outdoors, keeping graphics sharp and the product usable for much longer.

- This durability means fewer replacements, lower material consumption, and less waste over time.

Lower Carbon Footprint

Producing polypropylene from recycled material consumes less energy than creating new material. By choosing our ecorange products like Promeg PP or Corflute, you’re not only recycling but also cutting down on energy use and greenhouse gas emissions.

Real-World Usability

For industries like signage, packaging, storage, and displays, Promeg PP and Corflute consistently outperform biodegradable and cardboard alternatives because:

- They last longer in harsh conditions.

- They keep their structural integrity.

- They’re cost-effective in the long run because fewer replacements are needed.

Recycling vs. Biodegradability: The Practical Choice

While biodegradables might sound good in theory, they often don’t deliver in practice. Recycling materials like Promeg® polypropylene and Corflute® creates a more reliable, accessible, and truly circular sustainability model.

By investing in recyclable solutions, businesses and consumers alike can:

- Reduce waste to landfill

- Lower overall carbon emissions

- Rely on materials that perform in real-world conditions

Microplastics: The Hidden Hazard for Wildlife

Beyond the environmental waste and landscape impact, plastic materials, especially those that break down into microplastics, present a serious danger to fauna. When non-recycled plastics or degraded bioplastics fragment over time, tiny particles can be ingested by animals at all levels of the food chain, from insects and birds to marine life and mammals. These microplastics can clog digestive systems, reduce nutrient absorption, and cause physical harm. In waterways, they also carry toxins and chemicals that bio-accumulate in organisms. In contrast, durable, recyclable materials like Promeg® polypropylene and Corflute® are less prone to fragmenting into dangerous microplastics, particularly when properly collected, recycled, and kept out of natural environments.

Final Thought

Of course there are many appropriate applications for biodegradable plastics, but when you compare the value and applications that people use Corflute® for, the benefits just don’t stack up.

Genuine Australian Made Corflute® is designed for repeat use – designed for the long haul. And then it can be recycled and reused again and again at Corex Recycling. A biodegradable flute alternative is not a comparable substitute, and if it enters our closed-loop recycling stream, it contaminates polypropylene materials and ends up becoming of landfill value.

Sustainability isn’t just about how fast something breaks down, but rather about creating closed-loop systems that keep materials in use for as long as possible. Promeg® Polypropylene and Corflute® prove that recycling, durability, and reuse are powerful tools in building a genuinely sustainable future.

Get in touch to find out more hello@corex.com.au

Corex & Sustainability

Everything that Corex makes is invited back for recycling and reuse in our Corflute® and PROMEG® products.

What happens to the Corflute® returned to us?

- Corex Recycling process and recycle every kilogram of plastic received

- After processing the signage returned, the repelletised polypropylene

- All of the processed material returned to us from our customers had a use within Corex

Unfortunately, much of the ‘Corflute’ that is used around Australia is one of many overseas products. It’s not ours, and not made in Australia.

Recycling is not easy or without cost, but we encourage everyone to purchase Australian made Corflute® where possible to help us to create a truly circular product.

Corex is proudly Australian. Our products are designed for the circular economy.

HOW TO: Prepare Corflute® for Recycling

Corflute® & PROMEG® Recycling Booking Form

Contact the team at Corex for more information hello@corex.com.au

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields