Our laboratory facilitates material classification for suppliers, processors, manufacturers, and end users.

What does the Corex Plastics Lab do?

The Corex Lab provides science and engineering based technical support to ensure your plastic products meet their application, specification, & mechanical design requirements.

Our laboratory facilitates material characterisation for suppliers, processors, manufacturers, and end users of plastics.

Read about the various Corex Plastics Lab tests below.

To contact us about the Corex Lab, click on the Contact us button. Then, in the drop-down question, “Let us know what you are interested in?” choose “Corex Lab”.

Testing

The Corex Lab is comprehensively equipped to test many materials and products.

Combining our vast experience in polymer engineering whilst keeping up to date with applicable standards, we can create test programes to meet the requirements for your application.

Our laboratory is equipped with the following:

- Instron tensile machine 5543

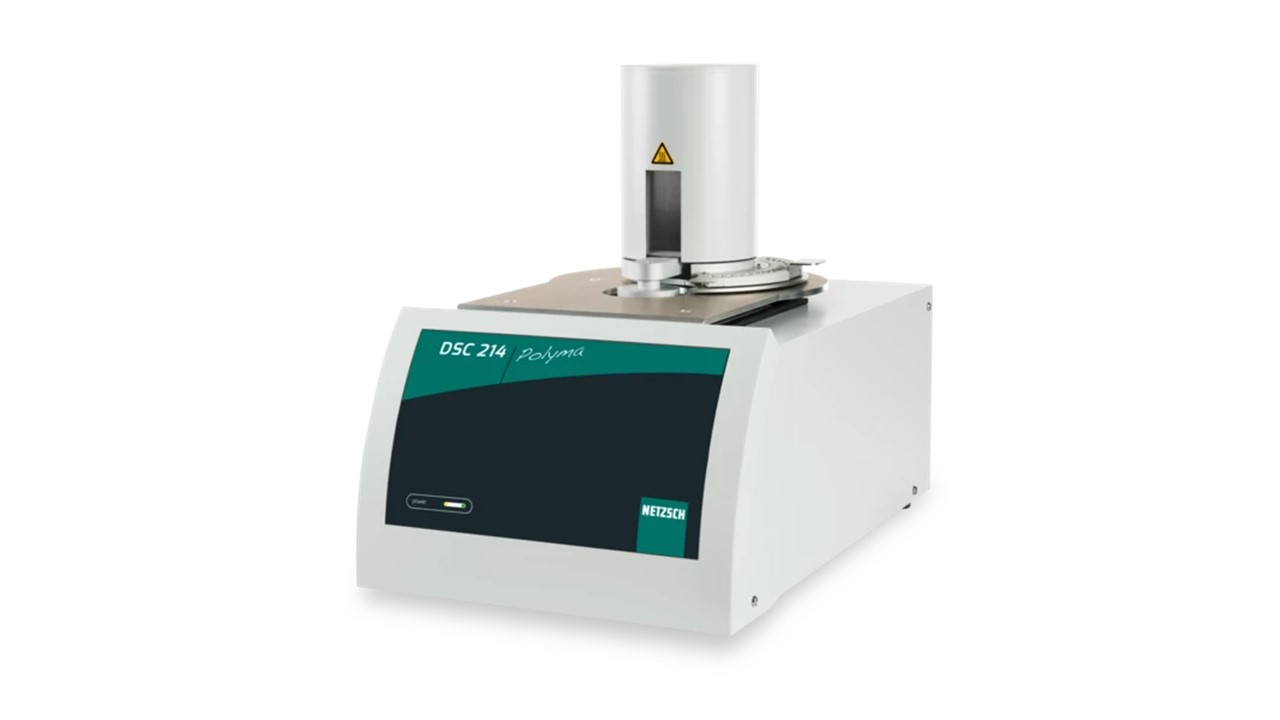

- Netzsch DSC 214 Polyma

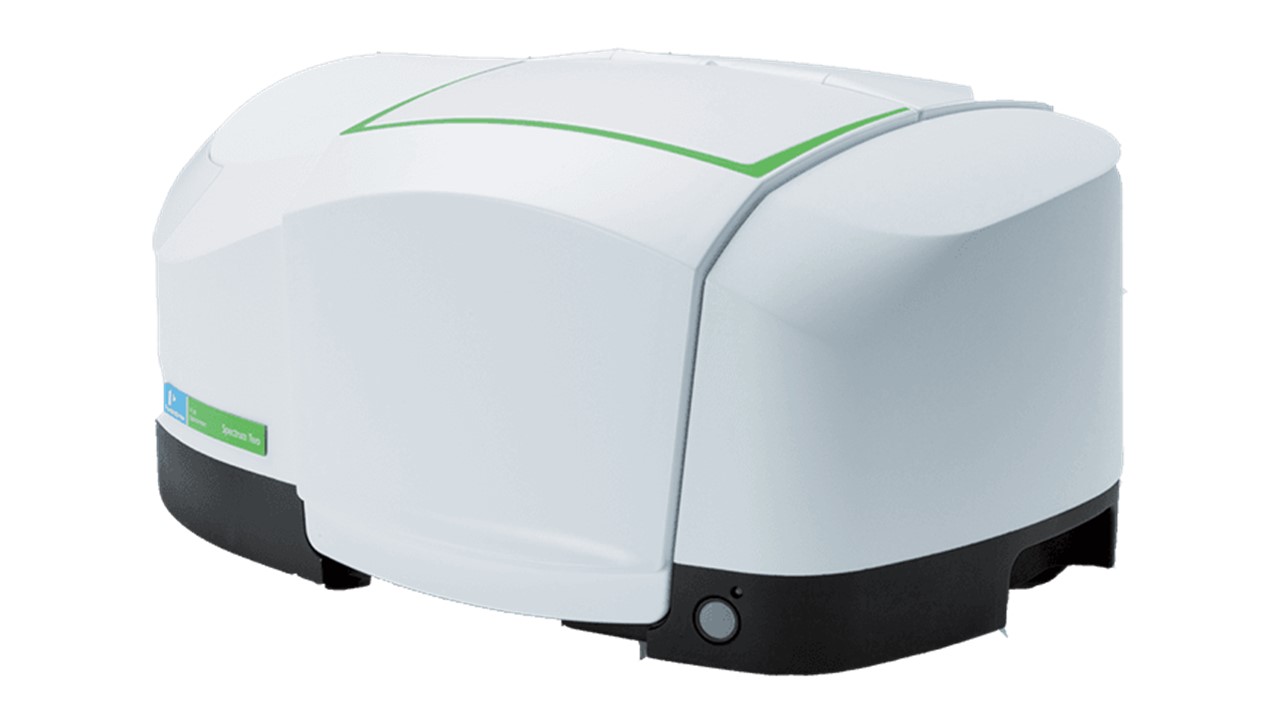

- FT-IR Spectrometer PerkinElmer Spectrum Two

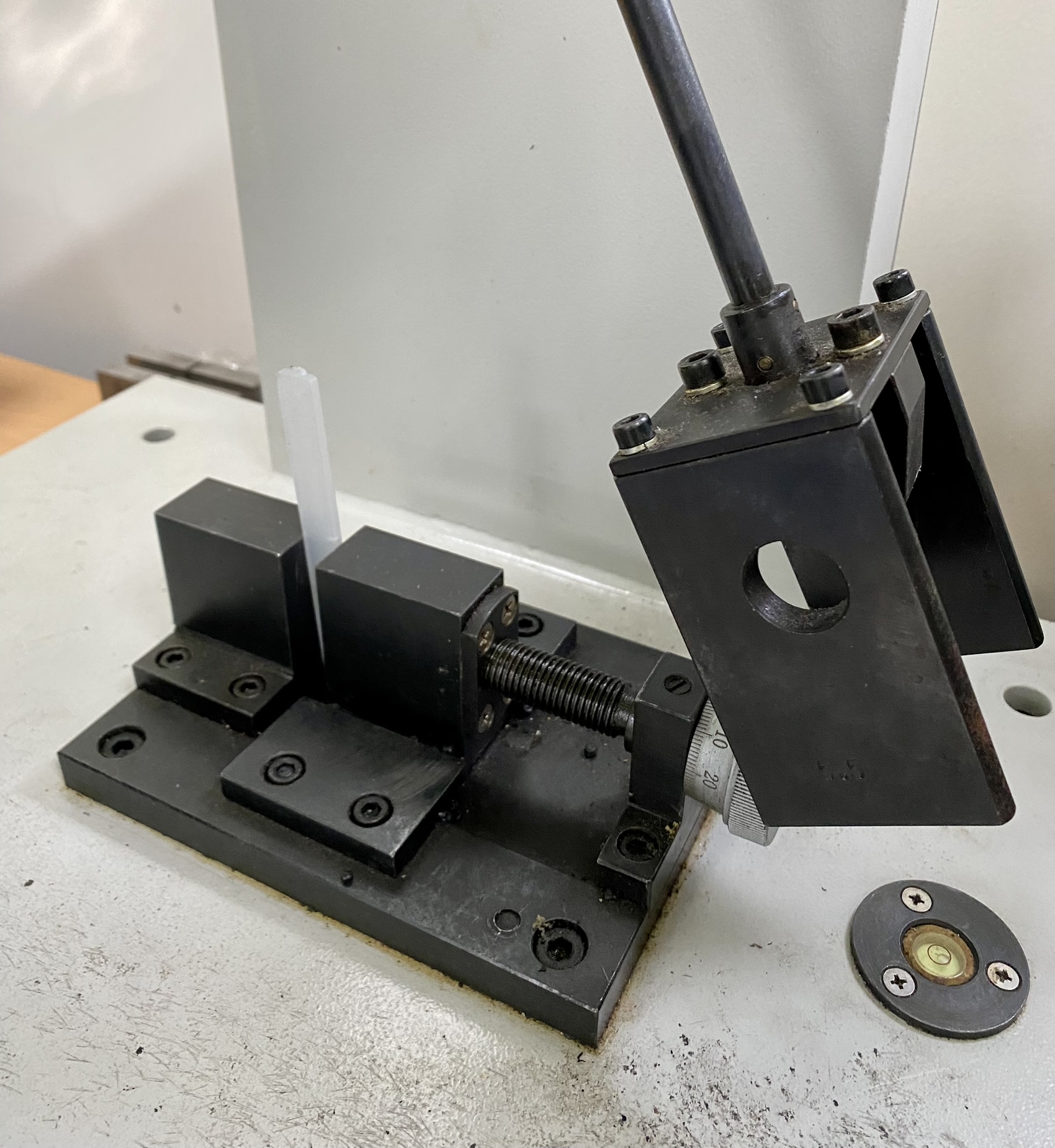

- Impact tester (Izod and Charpy)

- Instrumented impact tester

- Crush testing equipment

- Accelerated weathering Q.U.V

- Taber abrasion test

1. Tensile Test

Tensile testing and material characterisation are crucial for manufacturers and researchers in all industries.

In order for a material to be selected for a new product or use, researchers must ensure that it can withstand the mechanical forces that it will encounter in its end-use application.

Tensile testing is also used by quality assurance departments to ensure that batches of finished product are meeting the required specifications for tensile properties. This is important from both a safety and a business perspective, as defective products can be dangerous to the end user and can also cause significant harm to manufacturers in the form of product delays, lost revenue, and damaged reputations.

2. Differential Scanning Calorimetry (DSC)

DSC is a thermal analysis technique in which the heat flow into or out of a sample is measured as a function of temperature.

It is a very powerful technique to evaluate material properties such as glass transition temperature, melting, crystallization, specific heat capacity, cure process, purity, oxidation behaviour, and thermal stability.

3. Fourier Transform Infrared Spectroscopy (FTIR)

Fourier Transform Infrared Spectroscopy (FTIR) Analysis or FTIR Spectroscopy, is an analytical technique used to identify organic, polymeric, and, in some cases, inorganic materials.

The FTIR analysis method uses infrared light to scan test samples and observe chemical properties.

FTIR spectroscopy is used to identify compounds such as;

- Compounded plastics

- Plastic blends

- Fillers, paints, rubbers, coatings & resins

- Adhesives

FTIR analysis helps clients understand materials and products.

4. Impact Test

Impact testing is used to determine material behaviour at higher deformation speeds. This classical pendulum impact testers determine the impact energy absorbed by a standardized specimen up to break by measuring the height of rise of the pendulum hammer after impact.

At Corex Plastics lab we can do both Izod and the Charpy test. Both involve striking a standard specimen with a controlled weight pendulum travelling at a set speed.

This test measures the ability of a material to withstand impact, used by engineers to predict its behaviour under actual conditions.

5. Puncture and impact resistance measurement

Instrumented Impact Tester provides a versatile and accurate way to characterise impact and puncture properties of wide range of materials such as plastics, composites, films, pipes, soft metals, wood, laminates etc. The machine employs a powerful pneumatic ram which drives an impact element into a specimen at high speed.

Data collected during a single impact can thus determine energy, load and deformation at yield and break points, indication of crack initiation and propagation and measure of sample stiffness.

Corex lab can accurately measure and quantify the effects that stressors such as UV radiation, broad-band solar radiation, temperature, humidity, salt-fog, etc.

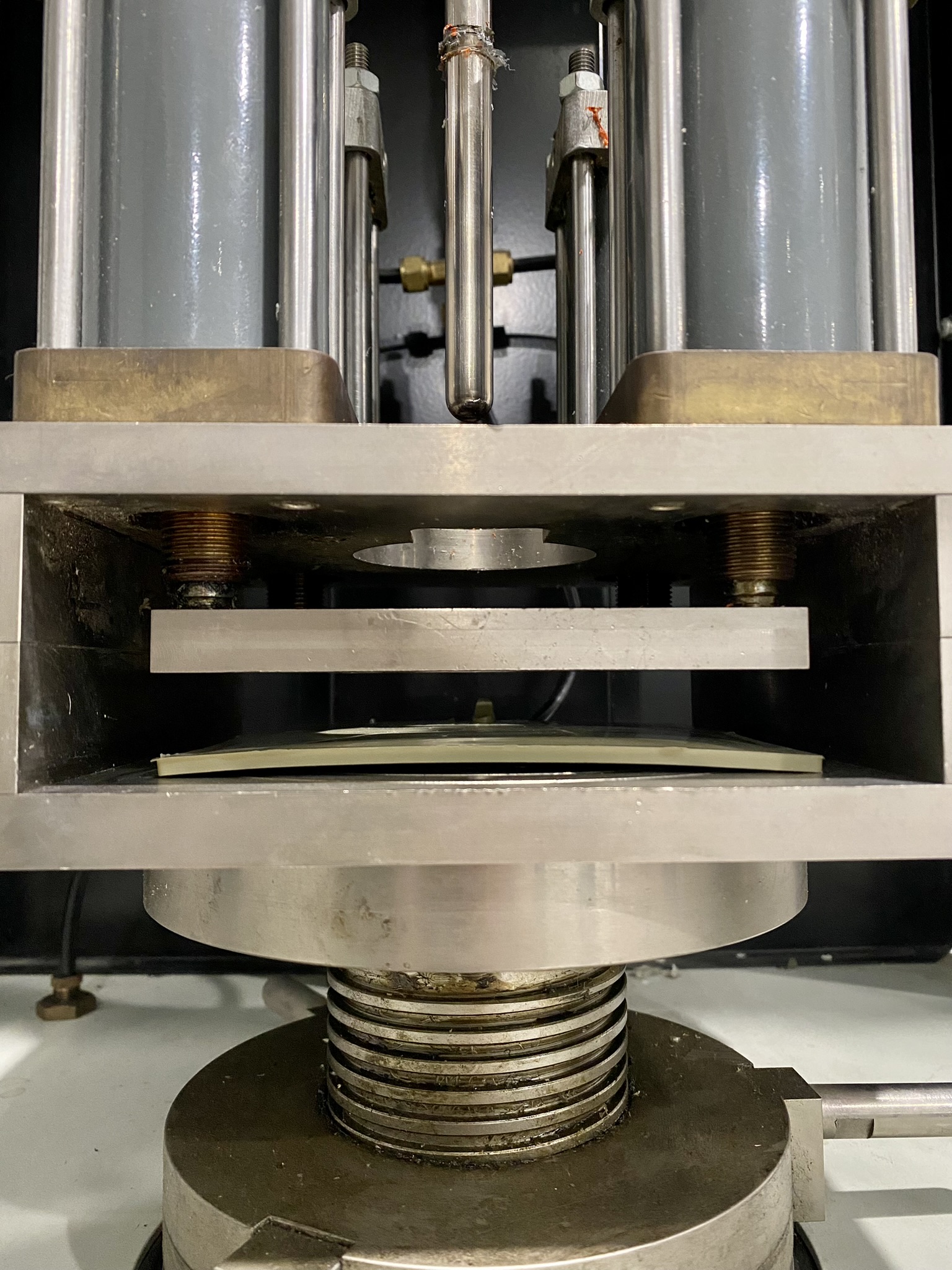

6. Flat Crush Testing

Flat crush test is designed to measure the resistance of corrugated paperboard to flute crushing. This is a very useful measurement when determining the amount of pressure applied during the printing process for corrugated boxes, for example.

This test measures the crush strength of flute-board in accordance with AS 1301.429S- 2017. The Flat Crush Test evaluates the crushing resistance of the flute structure of the board when subjected to loads applied perpendicular to the surface of the board and under conditions which restrain lateral motion of the facings.

7. Accelerated weathering testing

Accelerated weathering test methods simulate extreme weather conditions using special environmental chambers and instruments that speed up the weathering process.

Environmental effects can cause a change in colour, cracking, corrosion and deterioration of a product’s exterior and interior.

8. Taber Abrasion

ASTM D1044 (Haze), ASTM D4060 (Weight Loss)

The Taber abrasion test assess how well a plastic can withstand abrasion, which refers to the mechanical action of rubbing, scraping, or erosion.

Comparing abrasion resistance can be challenging, but commonly evaluated factors include changes in haze or weight loss.

The test involves measuring the initial haze or weight of a test specimen. The specimen is then placed on the Taber abrasion tester, and a load of either 250, 500, or 1000 grams is applied to the abrader wheel, which is allowed to spin for a specified number of rotations.

Different types of abrading wheels are used depending on the requirements.

After the test, a measurement is taken to assess the haze or final weight. The load and wheel settings can be adjusted based on the hardness of the material being tested.

Products that never go into the ground

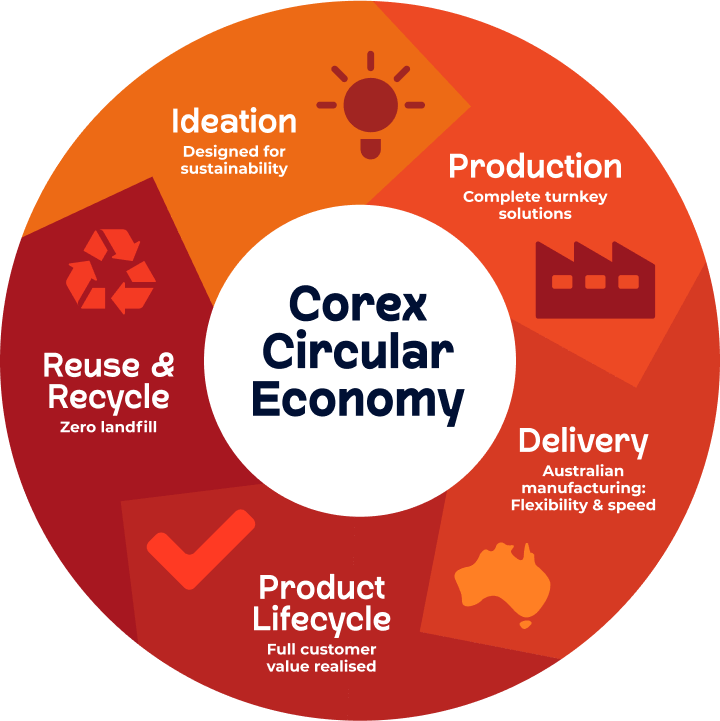

At Corex, we believe plastic can be of great benefit to our society, when managed responsibly. We are industry leaders in facilitating the truly sustainable existence of plastic in our world.

Additional services we offer

Corex’s local assets, experience and general team know-how allows us to offer services at every stage of a product’s lifecycle.

How we can help your industry

Corex’s local assets, experience and general team know-how allows us to offer services at every stage of a product’s lifecycle.

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields