No Time To Waste

Labelmakers Group

Corex Recycling

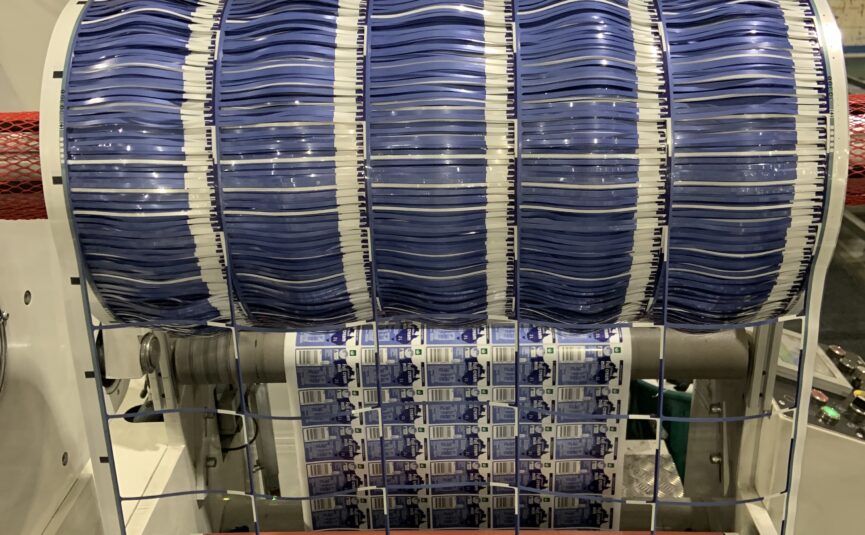

Recycling polypropylene matrix scrap from label making process.

You know that every piece of Corflute® that’s reached the end of its life is invited to be brought back to Corex for recycling. But did you know that Corex also recycles polypropylene from other manufacturers who produce packaging for some of Australia’s most iconic consumer brands?

Learn more about the successful partnership between Labelmakers Group and Corex Recycling that has turned one company’s waste into another company’s product of tomorrow.

Labelmakers show why they are market leader

Spanning eight manufacturing locations throughout the Trans-Tasman region, Labelmakers Group (Labelmakers) is the leading supplier of labels and packaging solutions supporting Australia’s most recognised brands in Australasia.

Sustainability and environmental responsibility is in Labelmakers’ DNA, driving their commitment to “Environment Conscious Products & Processes”, especially to reducing landfill.

Labelmakers are proud to be able to say that “process waste going to landfill was reduced by 20% since 2016 despite a significant increase in materials being processed through the facility”. And they’re achieving their goals with help of Corex Recycling.

Achieved sustainability goals with the help of Corex Recycling

The story begins when Labelmakers were seeking a solution for sustainably disposing of their polypropylene (PP) scrap (post industrial waste). In particular it is the matrix waste that is most problematic because it comprises different materials

“Being so sticky it creates a considerable challenge for collection and recycling. explains Damian Smyth, Labelmakers Group, Environment and Sustainability Manager.

The solution: Labelmakers’ unique processing technology plus Corex innovation

Labelmakers engineered a solution, integrated into the label converting process, that effectively separates the disparate components of the matrix waste.

Through close collaboration with Labelmakers, Corex then developed a means of capturing and treating the sticky matrix material and reusing it through their Recycling facility. This has been a wonderful example of putting the theory of the circular economy into practice.

The results: PP waste prevented from going to landfill

In finding a solution for the problematic PP matrix scrap we are very proud to say that the waste from our main raw material is now prevented from going to landfill

Going even further than the Australian Packaging Covenant Organisation to drive innovation

When you’re leading change, it’s about more than just meeting existing requirements, you need to commit to pushing the boundaries. Labelmakers’ innovations, in conjunction with Corex, are helping educate customers about what’s possible and encouraging and supporting them to find new and better solutions. Helping meet that demand and desire is creating a fertile ground for new and genuine solutions, with companies like Corex and many of Labelmakers’ customers.

“We are signatories to the Australian Packaging Covenant Organisation (APCO) and our innovation agenda is aligned to achieving the 2025 Packaging Targets for both sustainable label design and diversion of our process waste”. Explains Jess Walters, Labelmakers, Head of Sales and Marketing.

“Corex have been extremely proactive and it’s a great outcome for both businesses because waste recovery solutions at this end means more feedstock for Corex. Our focus at this stage is our Somerton site in Victoria, but our intention is to expand this recycling initiative to our other sites too”

Supporting Australian made

There’s clear synergy between Labelmakers and Corex, both Australian-owned manufacturing companies. Supporting and driving the local economy and innovation is a key part of their business focus. The owners of Labelmakers, the Bamford family have a personal interest in investing locally and supporting local innovation and development in environmental solutions in particular.

“We see that our customers also want to be able to tell their own story about the importance of Australian-made and being a responsible environmental citizen. We know firsthand that Australia’s some of largest FMCG manufacturers are committed to ‘zero waste to landfill’. They want to know what we’re doing; they ask us what we’re doing next, and we’re proud to be able to advise and support them in a material way.”

No time to waste!

Plastic’s recyclable / re-usable qualities mean it’s perfectly suited to a closed loop system. Plans to keep as much material as possible in circulation are being supported by new innovations in the infrastructure and systems around the collection of single use plastic and reuse as a feedstock.

But that’s not all, Labelmakers are currently working closely with Corex to develop a new product that will further enhance circularity within the label supply chain., due for release later this year

Learn more about Labelmakers

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields