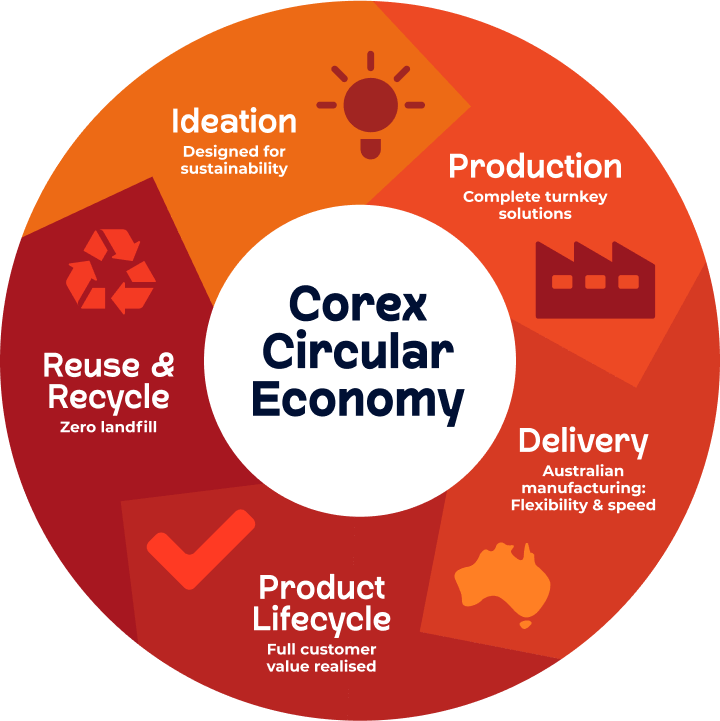

Overview of Corex VLDPE

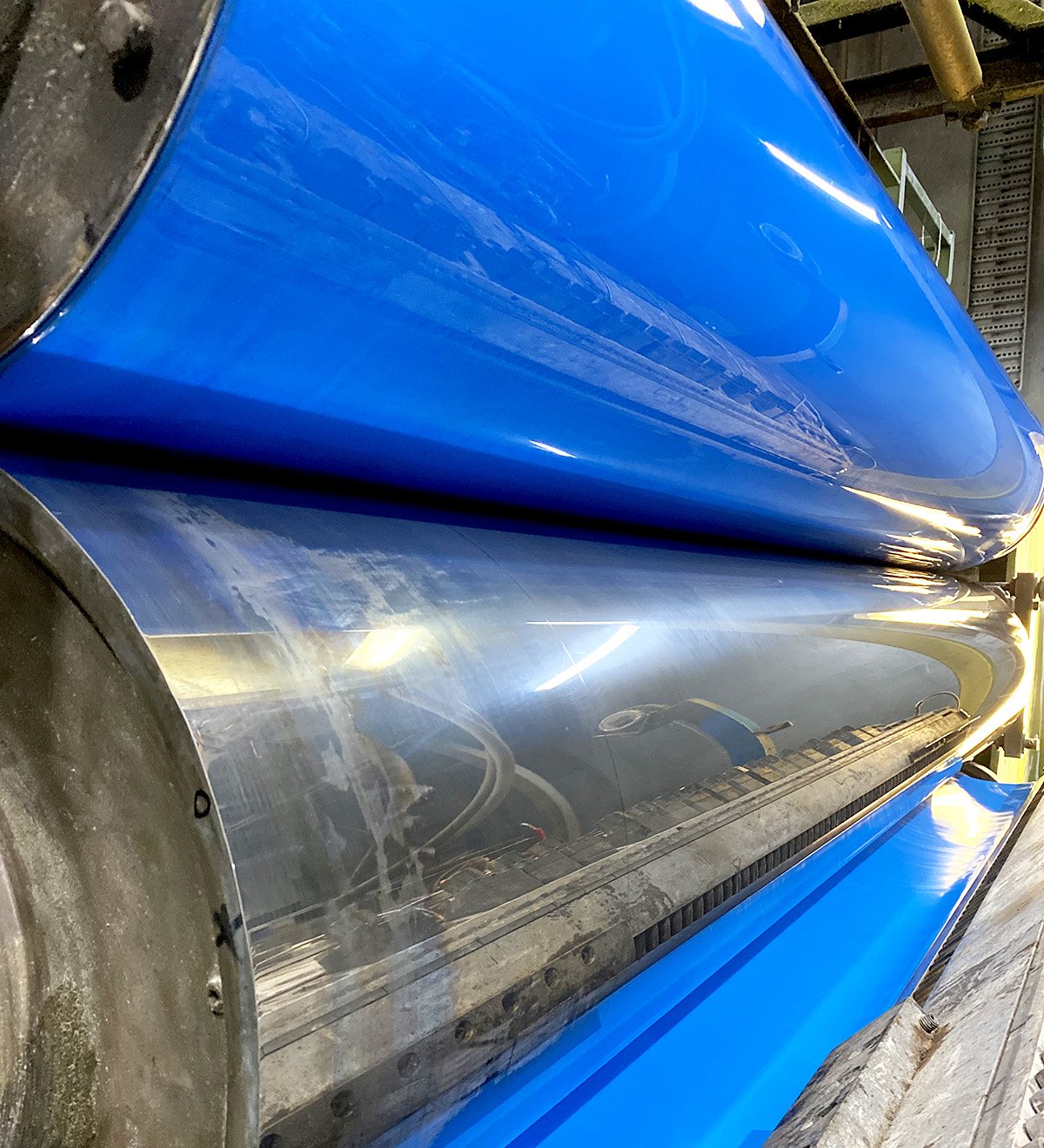

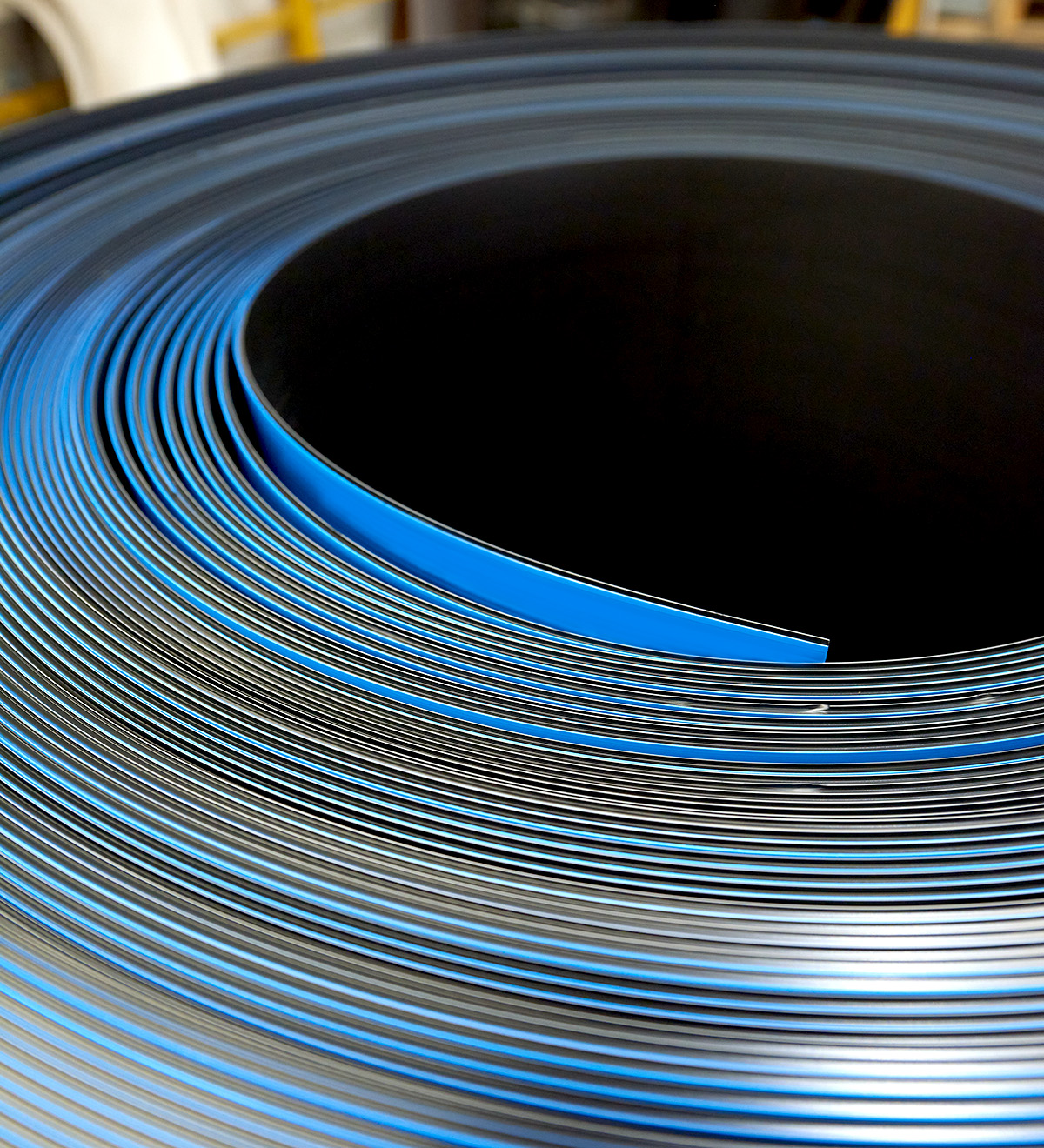

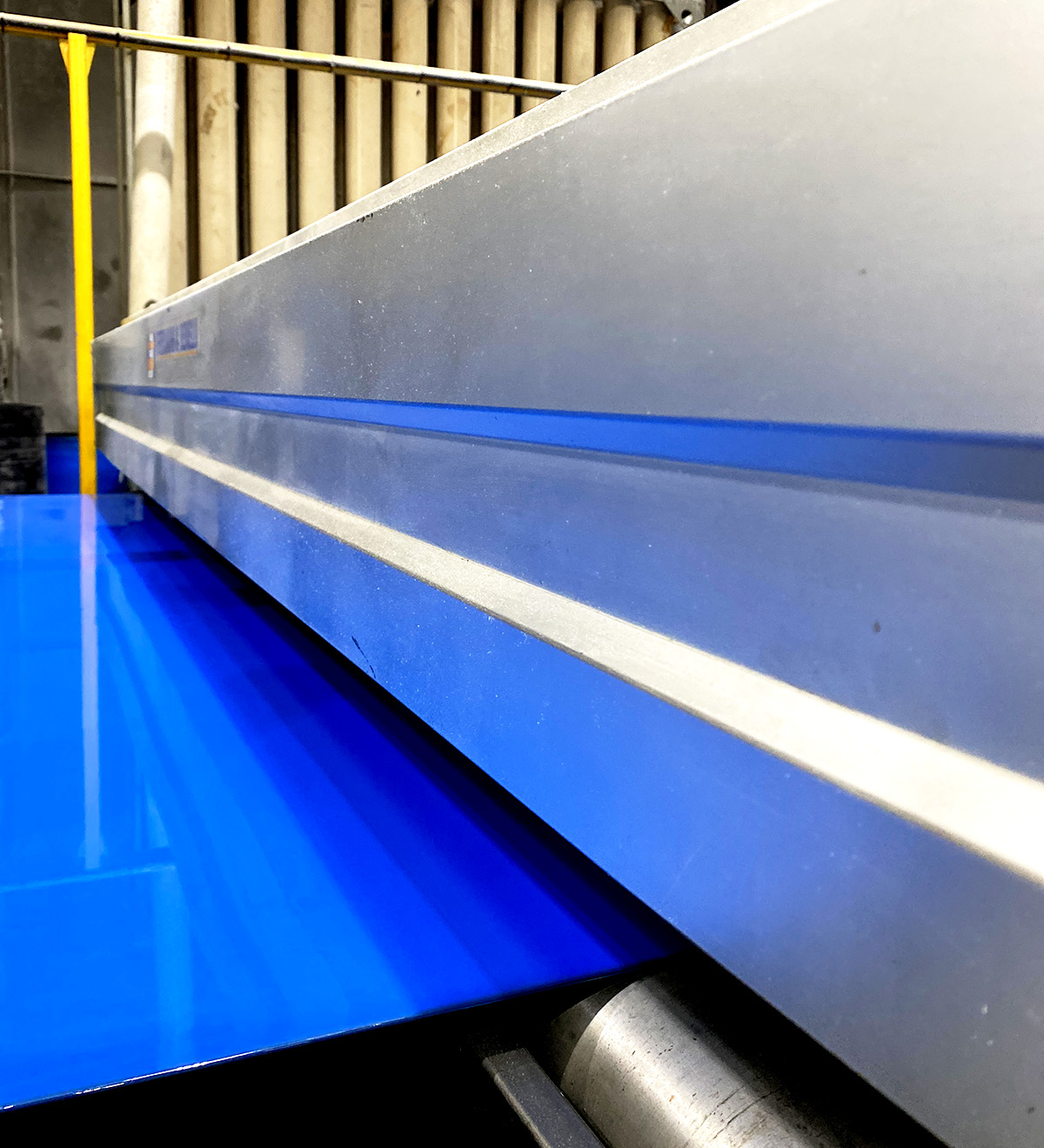

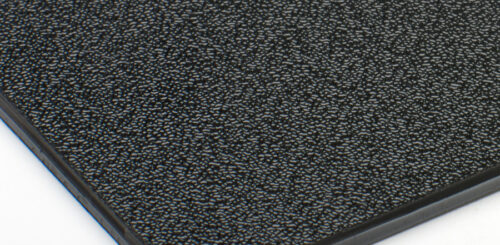

Corex® VLDPE sheet is a waterproofing membrane made with a formulation based on very low-density polyethylene giving it excellent flexibility and weldability.

Used in applications requiring high elongation and ductility. This product has high chemical and tear resistance.

What is VLDPE?

VLDPE stands for Very Low-Density Polyethylene, a type of polyolefin with a lower density and higher branching than standard LDPE (Low-Density Polyethylene). This molecular structure gives it:

- Excellent flexibility and stretch

- High puncture resistance

- Low permeability to water and gases

Order VLDPE sheets and rolls in bulk starting from 4 tonnes.