Polypropylene vs PVC. Which is best?

Polypropylene (PP) is one of the most neutral plastics containing only two elements: carbon (C) and hydrogen (H). PVC (polyvinyl chloride) plastic, commonly referred to as vinyl, is one of the most hazardous consumer products ever created.

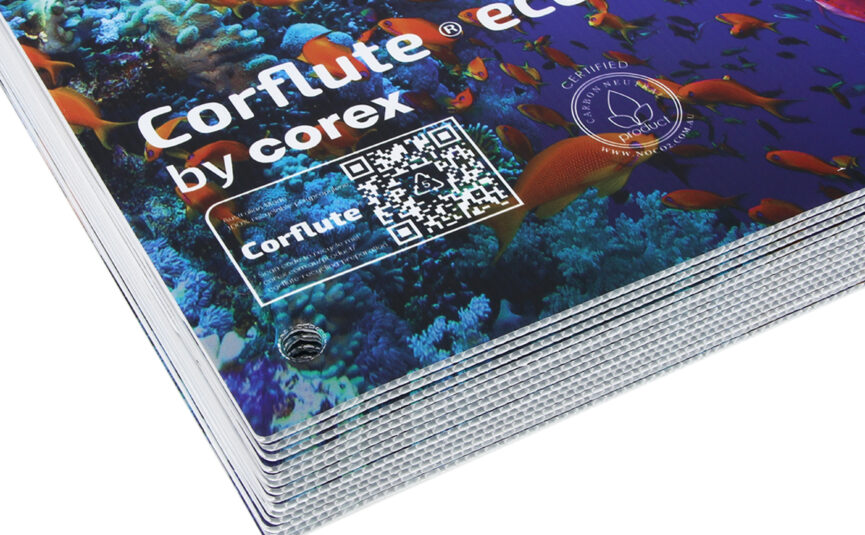

Corflute® and PROMEG® are Australian-made plastic sheets made from polypropylene. Corflute® is a twin wall profile polypropylene (PP) sheet defined by a series of flutes. PROMEG® sheets are also made from polypropylene, but have a solid profile. Both are manufactured by Corex Australia and are easily recyclable.

PVC (polyvinyl chloride) plastic and is commonly referred to as vinyl.

Read about the 5 key differences between PP and PVC

1. PRODUCTION

PP sheet is manufactured from propylene monomer, a relatively safe gas which is a waste by-product of the petroleum industry. It used to be burned off into the atmosphere, contributing to greenhouse gas emissions. Using more PP in products helps reduce greenhouse gas emissions. PP is made up from carbon and hydrogen and is manufactured without any dangerous emissions.

In contrast, PVC is manufactured with the addition of toxic additives, which can make the PVC product itself harmful to consumers. These chemicals can evaporate or leach out of PVC, posing environmental and irreversible health risks to consumers.

PP production consumes less energy compared to PVC, contributing to its lower carbon footprint. The absence of chlorine in PP eliminates the risk of producing dioxins during manufacturing or disposal.

2. LIFECYCLE

PVC’s entire life cycle, from production through use and disposal, has a negative impact on human health and the environment. PVC requires a large amount of heavy metals like lead to stabilise it, which are toxic both during the life cycle of a product and after disposal. Flexible PVC also relies heavily on plasticisers, such as phthalates, at concentrations of 30-50%. These plasticisers are mobile by nature and may migrate, posing health risks.

Promeg PP sheet contains no lead or other heavy metals and avoids the use of toxic plasticisers.

PP’s inert chemical structure makes it less prone to environmental degradation, ensuring it remains safe during use and disposal. Unlike PVC, PP does not release harmful chemicals over time.

3. RECYCLE

PP is 100% recyclable. During recycling, PP retains its strength and need not be ‘down-cycled’ into low-impact items. PP products are easier to recycle compared to PVC, which is difficult to recycle due to toxic additives that can contaminate the recycling process. PVC products pose significant long-term environmental threats, as additives can leach into groundwater when disposed of in landfill.

Recycling technologies for PP have advanced, allowing for closed-loop systems where recycled material can be used in high-performance applications. In contrast, PVC recycling remains limited and often results in downcycled products.

4. BY-PRODUCTS

During a fire situation, Corflute and PROMEG polypropylene burns to relatively harmless end products – carbon dioxide and water, alongside minimal amounts of carbon monoxide and soot. Burning PVC plastic, however, releases dioxins, some of the most potent synthetic chemicals ever tested, which can cause cancer and harm the immune and reproductive systems.

PP’s combustion produces lower smoke density compared to PVC, making it a safer option in fire scenarios.

5. SAFER ALTERNATIVE

It is important that a material uses a minimal natural resources, does not emit polluting substances, fulfills a long working life, and optimises aspects of reuse and recycling. PP fits these criteria.

The good news is that a safer, non-toxic, cost-effective alternative to PVC is readily available for virtually every use…

Australian made Corflute® and PROMEG® PP products.

Polypropylene: The Safe Plastic

Polypropylene (PP) is one of the most neutral plastics containing only two elements: carbon (C) and hydrogen (H).

PP sheet is manufactured from propylene monomer, a relatively safe gas which is a waste by-product of the petroleum industry. It used to be burned off into the atmosphere, contributing to greenhouse gas emissions. Therefore, using more PP in products may help to reduce greenhouse gas emissions. PP is manufactured without any dangerous emissions.

Polypropylene is an environmentally conscious option that provides a wide range of advantages compared to other materials. It is also a better option than other plastics, because it doesn’t release any toxic chemicals in the recycling process, has a relatively low carbon footprint (it consumes the least amount of energy during production), and is safe to human health.

Browse Corflute products

Contact Corex for your Corflute® and PROMEG® needs!

Corex is Australia’s exclusive manufacturer of Corflute® and PROMEG®.

We have a specialist range of products and services including polymer engineering, industrial design, printing, and fabrication so that we can offer a one-stop-shop to businesses seeking products made using Corflute® and PROMEG®.

Everything that we make is made to order so that can produce things to your exact specifications.

If you are looking to buy Corflute® or PROMEG® and products made from these plastics, the quality selection we produce is what makes us Australia’s leading plastic manufacturer and supplier.

Contact the team at Corex for more information.

About Corex

Corex is a unique Australian closed loop business with polypropylene sheet extrusion, fabrication, and recycling all on one site.

We have created a specialist range of products and services including polymer engineering, industrial design, printing, and fabrication so that we can offer a one-stop-shop to bulk handling manufacturers and producers.

Everything that we make is made to order so that can produce things to your exact specifications.

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields