From Waste to Wonder at Hort Connections

Filton Packaging

Corex Recycling, Corflute® eco

Recycling polypropylene scrap from packaging process. Exhibition stand design and construction.

Packaging, Retail Display, Recycling

You know that every piece of Corflute® that’s reached the end of its life is invited to be brought back to Corex for recycling. But did you know that Corex also recycles polypropylene from manufacturers who produce packaging items?

Read about how Australian manufacturer Filton Packaging who specialises in flexible packaging films and bags for the fresh produce industry, has turned their waste into a trade show stand at Hort Connections 2024.

Sustainable Packaging Leaders

Filton Packaging is an Australian manufacturer specialising in flexible packaging films, bags, perforation, and printing for various industries including fresh produce, bakery, grocery, and general packaging applications.

Filton Packging is committed to achieve the goals set out by the 2025 National Packaging Targets including using 100% reusable, recyclable or compostable packaging.

“We are spearheading the movement towards sustainable packaging solutions by providing material options that strongly support environmental initiatives, meeting the rising consumer demand for eco-friendly packaging. We ensure responsible management of our post-industrial BOPP/CPP material waste by collecting and recycling it back into Corflute® sheet, contributing to the circular economy and reducing our environmental footprint.” Ryan Worthington, CEO, Filton Packaging

Expo Stand Brief

Corex has been recycling Filton’s polypropylene skeleton waste for many years.

Polypropylene waste has a great value at Corex. Our goal is to use between 15% and 100% recycled content across our product range including Corflute® and PROMEG®. Using recycled content helps us to repurpose waste using fewer virgin polymers in our products.

Filton’s decided to take their sustainability efforts a step further and use Corflute® and PROMEG ecorange® for their trade show stand at Hort Connections. Corflute® eco is made using 50% recycled polypropylene sourced from Filton’s and other recycling partners.

The idea was to create the printed walls, signage, and propping elements from Corflute® and PROMEG® ecorange, and then return it to Corex Recycling after the show’s conclusion (Did you know that Corflute® can be recycled endlessly!?).

Filton’s supplied the graphic design, look, and feel for the 6-meter x 3-meter stand, then Corex’s design team brought their vision to life using a range of our recycled and recyclable products. We used one material only (polypropylene) for the entire stand with no tape or glue to keep the displays contaminant free and 100% recyclable after the show.

Materials & Construction

- Printed wall panels – 5mm Corflute® eco. Digitally printed and Kongsberg cut.

- 3D propping; Apple, flowers, fruit, and greenery – 5mm Corflute® eco. Digitally printed, Kongsberg cut, assembled, and ultrasonically welded to avoid tapes and other contaminants.

- Product display plinths – 0.8mm PROMEG®. Digitally printed, Kongsberg table cut, tabbed, and assembled.

Thank you to our recycling partners at Filton Packaging for working with us on your exhibition stand build and recycling post show.

Find out more about Filton Packaging.

Display Stands & Recycling

Polypropylene’s (made to use Corflute® and PROMEG®) recyclable and re-usable qualities means that it is perfectly suited to our closed loop operation.

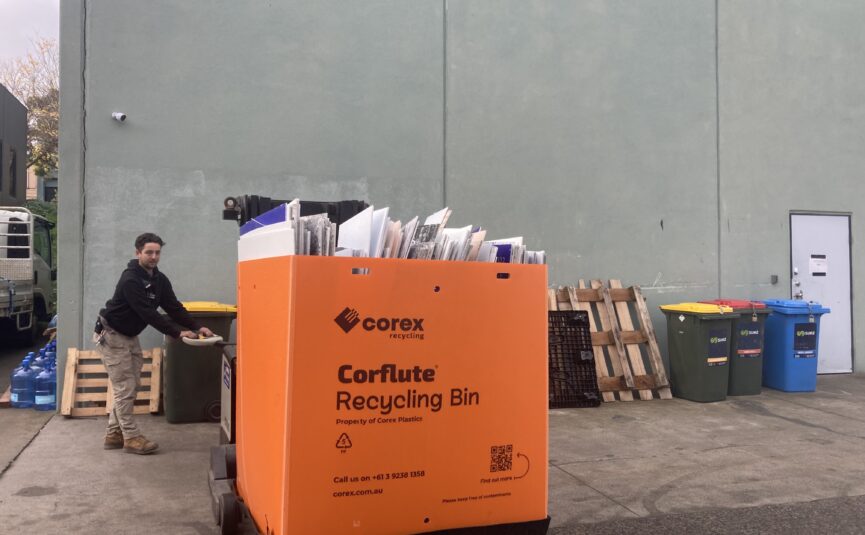

At the end of your Corflute® items life, we invite it to be brought back to Corex for recycling. We supply industrial size recycling bins called Corpaks® to our clients and distribution partners. We process and recycle all plastic we receive on site. All processed material returned to us has a use within Corex Plastics.

Reach out to us to find out more about creating a recyclable exhibition stand or recycling your Corflute® hello@corex.com.au

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields