National Recycling Week 2024

For the last 28 years, National Recycling Week has run in the second week of November. The purpose for the week is to focus on reducing, reusing and recycling to minimise strain on finite resources.

Corex takes great pride on our reduced footprint and have been trail-blazers in recycling and reusing plastics for over 20 years. We are the only company in Australia that offers Corflute® Recycling and at the heart of Corex is our Corflute® Recycling Program.

Corex is the exclusive manufacturer of the trademarked product, Corflute®. We work in a circular economy with a standalone recycling business. Together our goal is to bring back as much Corflute® as possible for recycling after it’s reached the end of its useful life.

To celebrate National Recycling Week, we are featuring three excellent initiatives in the recycling and reuse space.

1. Leaders in circularity: Repurpose, Recycle, & Remanufacture Corflute®

IVE Group (IVE) is Australia’s largest diversified marketing company. IVE produces Corflute® signage for Australia’s top retailers and was an early adopter of our Corflute® Recycling Program.

IVE are Corflute® eco-warriors and have strong sustainability procedures in place throughout their business. They maximise sheet yield to minimise Corflute® waste. They also donate any reasonable sized off-cuts to the SES who reuse it for temporary roof protection in emergency environments.

The rest of IVE’s Corflute® waste is sent back to Corex for recycling. The materials are then shredded, decontaminated, cleaned, and pelletised ready for reuse in our Corflute and PROMEG ecorange® products which are carbon Neutral Certified. IVE’s returned materials in the 2024FY period was equivalent to making approximately 14,000 recycled Corflute® sheets* (*based on 3mm standard sheet size).

All Corflute® produced in Australia for graphic applications by Corex, contains at least 10-50% recycled content returned by companies that use it for signage and other retail display products.

2. Pharmacy blister pack recycling in retail

This is a consumer initiative that we love about a wonderful consumer recycling initiative by Pharmacycle.

Pharmacycle’s blister pack recycling program

Earlier this week, Pharmacycle, in partnership with Chemist Warehouse and Kenvue (makers of CODRAL®), launched Australia’s largest blister pack recycling initiative nationwide after a successful trial last year. This is the only recycling program of its kind in Australia that provides a full recycling solution. Read the media release.

Every blister pack dropped off in the Corflute® bins at Chemist Warehouse are recycled. The purpose of this initiative is to provide a convenient way of returning empty blister packs in-store making recycling easy whilst avoiding empty packs ending up in landfill.

The Australian made Corflute® eco bin solution is the ideal choice due to its lightweight, strong and water-resistant credentials. Corflute® bins are excellent reusable and permanent retail display solutions, lasting more than 150 return trips on average, compared to just 4-5 for a cardboard alternative.

Congratulations on your wonderful recycling initiative Pharmacycle, Chemist Warehouse, and Kenvue!

3. More than PROMEG® and Corflute® recycling...

Did you know that Corex also recycles polypropylene from manufacturers who produce packaging items? Earlier this year we saw the opportunity to create wonder from waste for our partners at Filton Packaging.

Let me set the scene as simply as possible; We recycled our customers packaging waste, remanufactured it into Corflute® eco, designed and manufactured a whole exhibition stand, then brought everything back to Corex for recycling and reuse!

Australian manufacturer Filton Packaging specialise in creating high-quality flexible films, bags and sleeves designed to meet the unique needs of various FMCG industries. Corex has been recycling Filton’s polypropylene skeleton waste for many years.

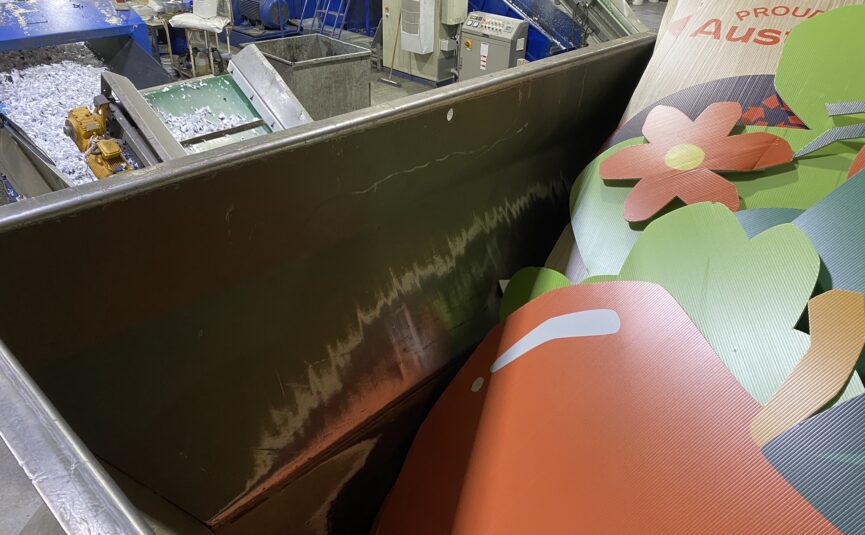

Earlier this year, Filton’s decided to take their sustainability efforts a step further and use Corflute® and PROMEG ecorange® for their trade show stand at Hort Connections. Corflute® eco is made using 50% recycled polypropylene sourced from Filton’s and other recycling partners.

Corex worked with Filton’s to create the printed walls, signage, and propping elements from Corflute® and PROMEG® ecorange. Read about the design.

It was then returned to Corex Recycling after the show’s conclusion and recycled!

Did you know that Corflute® can be recycled endlessly!? Watch the video below to understand our closed-loop process.

Corex & Sustainability

Everything that Corex makes is invited back for recycling and reuse in our Corflute® and PROMEG® products.

What happens to the Corflute® returned to us?

- Corex Recycling process and recycle every kilogram of plastic received

- After processing the signage returned, the repelletised polypropylene

- All of the processed material returned to us from our customers had a use within Corex

Unfortunately, much of the ‘Corflute’ that is used around Australia is one of many overseas products. It’s not ours, and not made in Australia.

Recycling is not easy or without cost, but we encourage everyone to purchase Australian made Corflute® where possible to help us to create a truly circular product.

Corex is proudly Australian. Our products are designed for the circular economy.

HOW TO: Prepare Corflute® for Recycling

Corflute® & PROMEG® Recycling Booking Form

Contact the team at Corex for more information hello@corex.com.au

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields