Overview

What is Cor-Vent®?

Cor-Vent® is a passive Roof Ventilation device with compliance to Code NCC2022 ABCB housing Provision Part 10.8.3 & Vol1 F8D5 requirements. Designed to allow passive airflow over fascia and pliable membrane (sarking) or flashing to reduce the risk of moisture and condensation in the roof attic.

Cor-Vent® Range

We offer Cor-Vent® products that cater to various roof pitches from 0°~75°.

Design

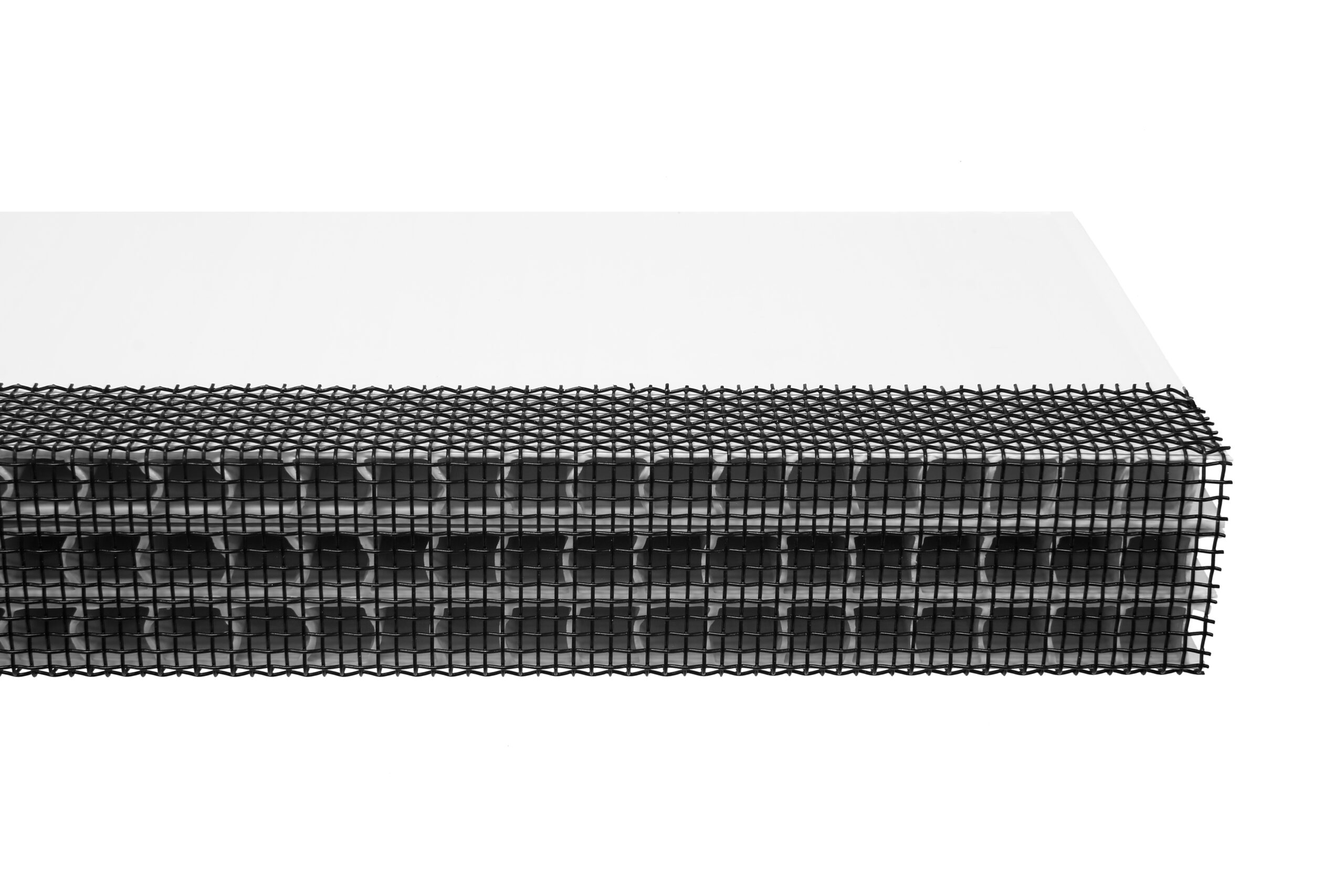

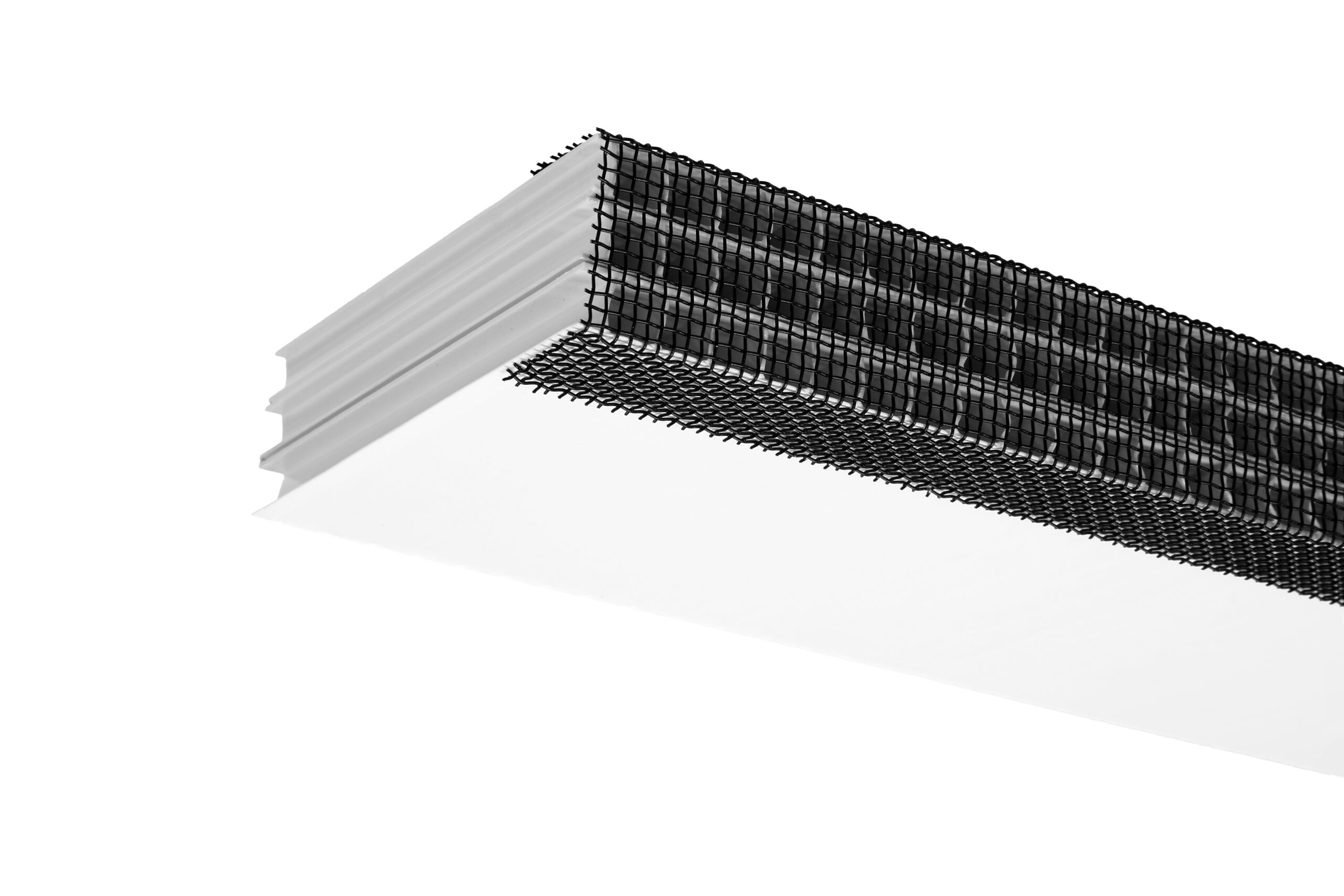

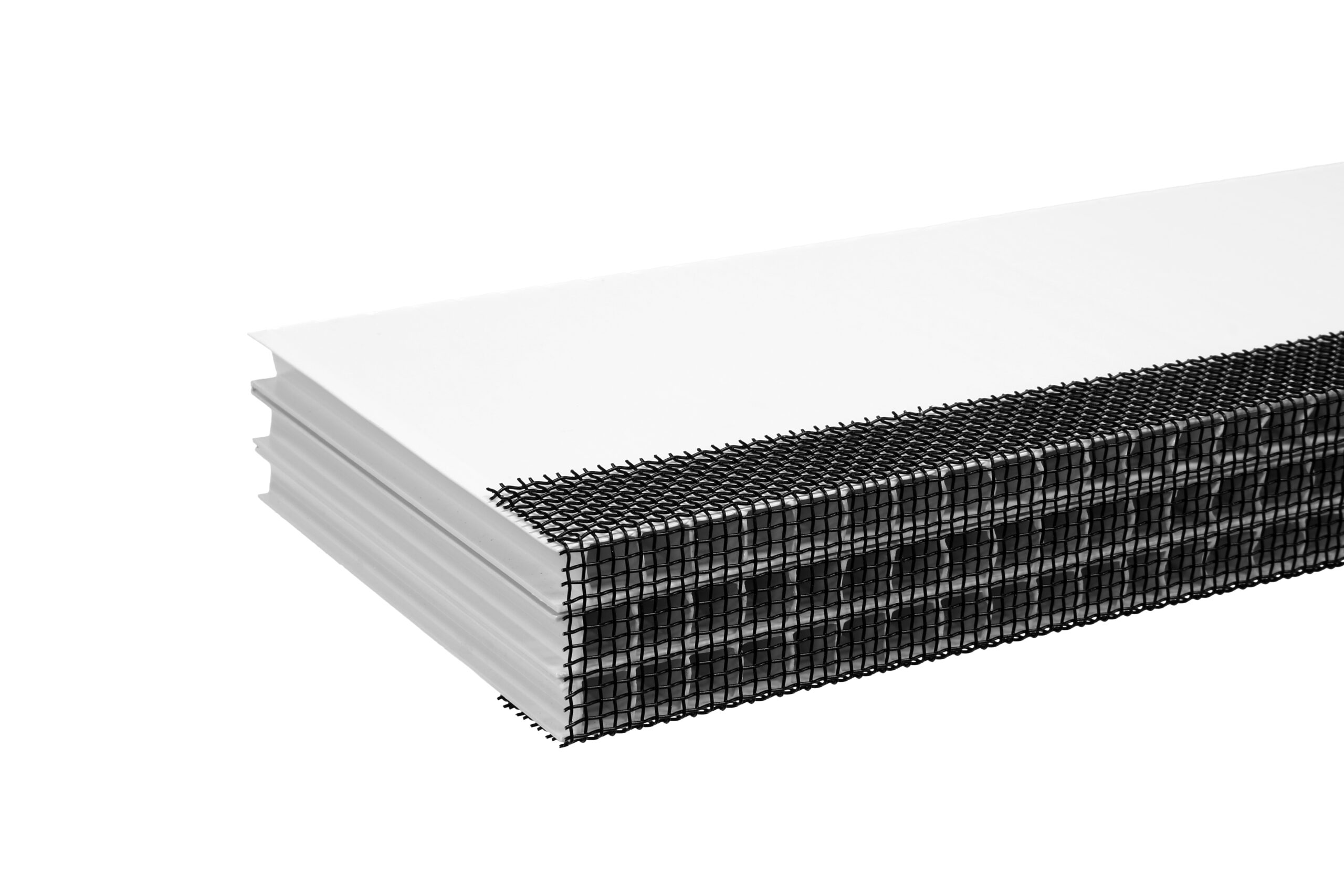

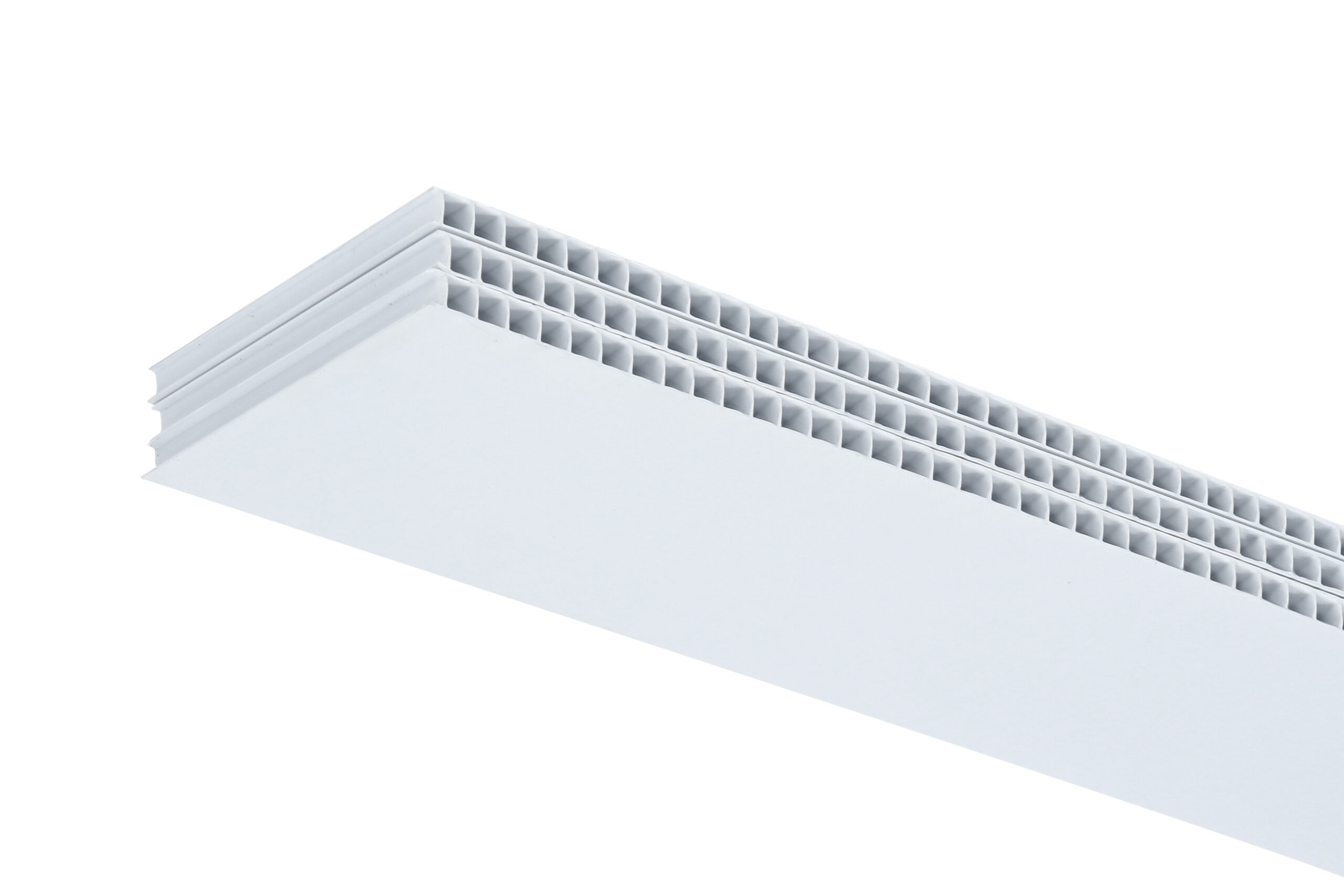

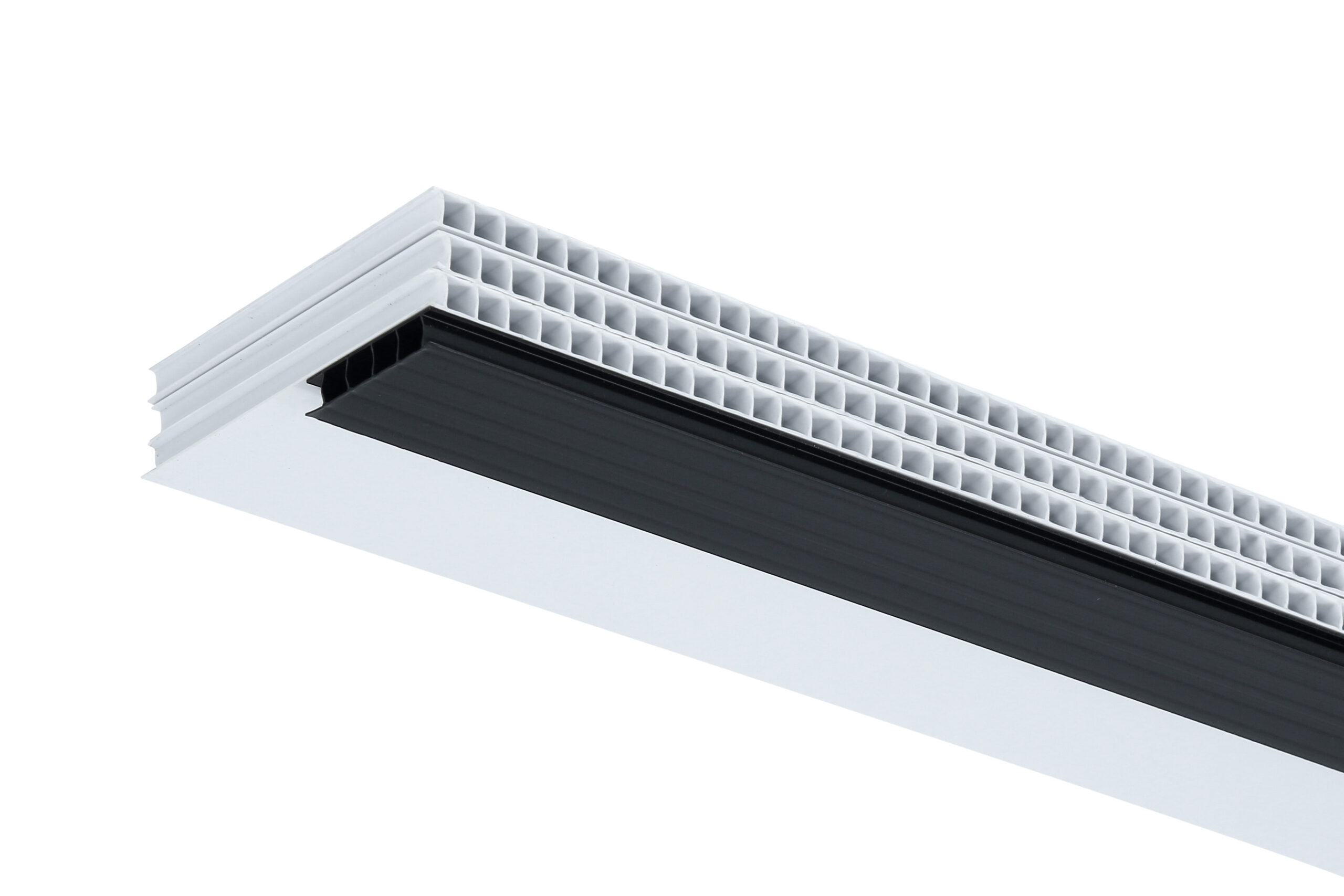

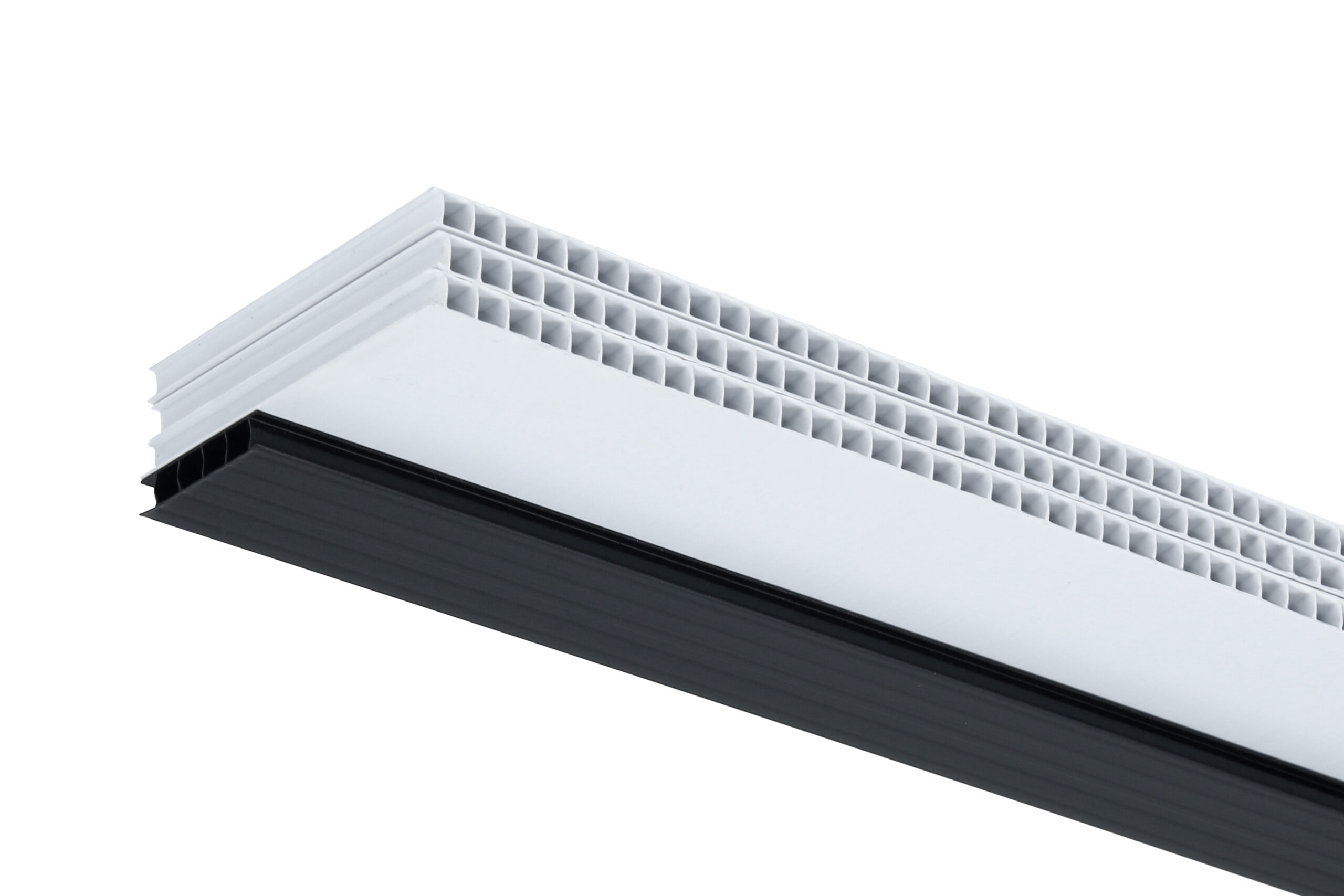

Cor-Vent® products are made from Australian made fluted polypropylene board (Corflute®); a robust substrate perfectly suited to roof ventilation requirements.

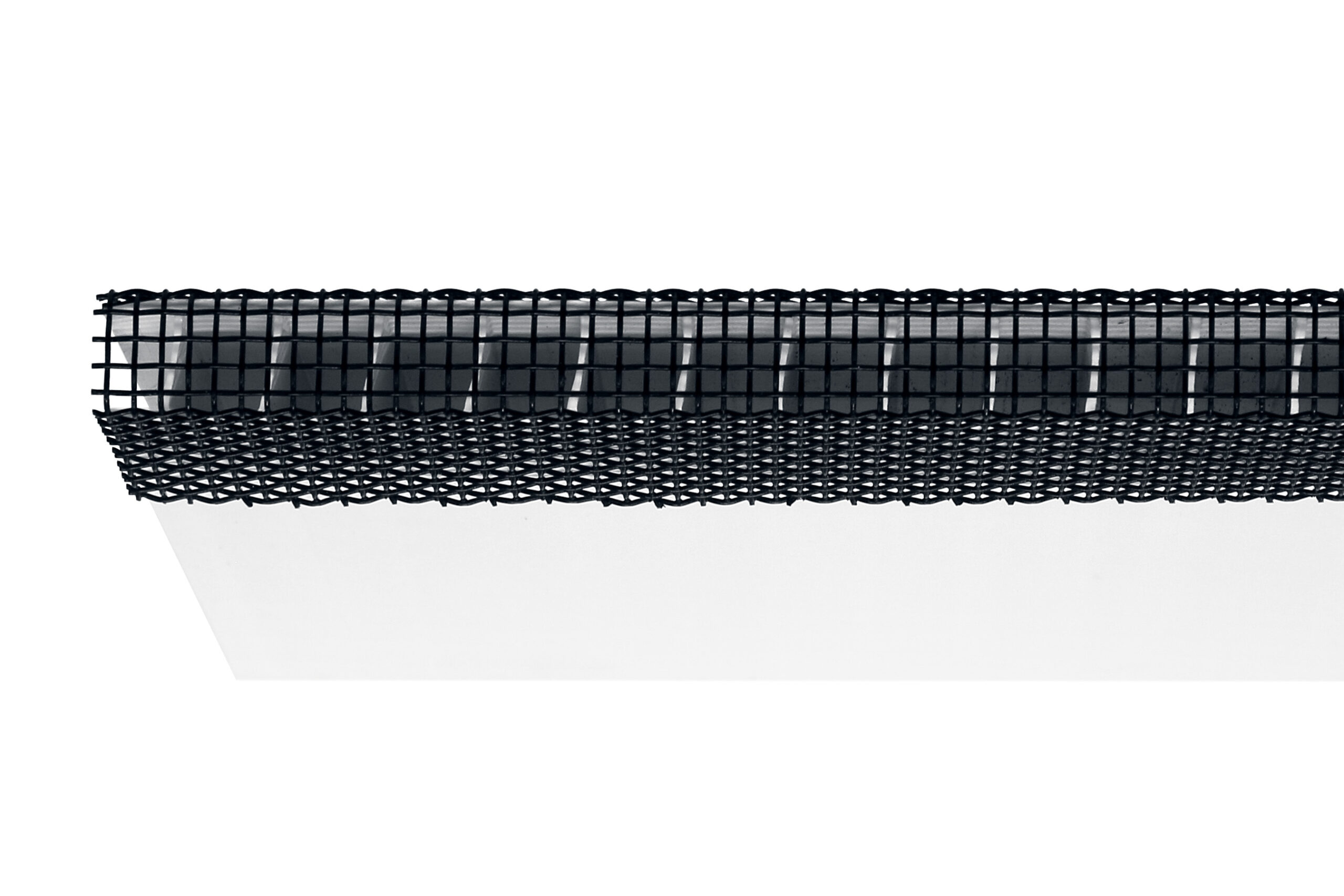

The Cor-Vent® 8K and 5K products include a 45° cut on both open ends (flute openings). Cor-Vent® 25K product has a 90° cut on both ends. The open ‘flutes’ improves airflow and helps avoid possible blockage from overlapped sarking.

Installation

Cor-Vent® product installations do not require any special tools, training, or major changes to the roof build. Cor-Vent® Installation Guides are included in the Product Information Download Forms above.

Certification

Cor-Vent® meets the DTS airflow opening requirements per NC2022, including BAL Zones.

Contact our Cor-Vent® specialists for additional information at building@corex.com.au or download Cor-Vent® Order Form below.

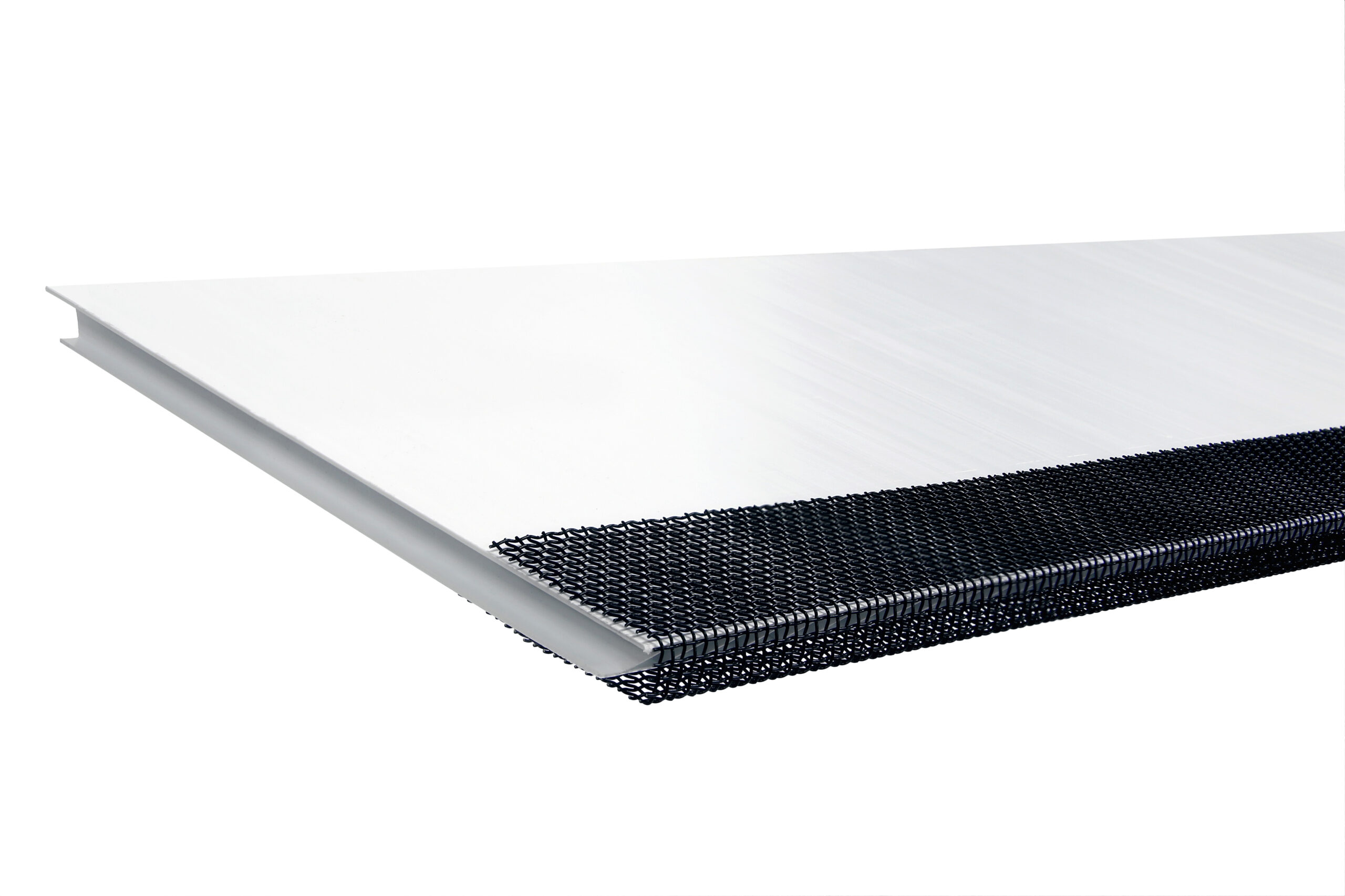

Image: Cor-Vent® 8K FR BAL 200. For standard pitch roofs – 15°~75°. Cor-Vent® is Australian designed and made locally from Corflute®. Patent pending: 541217AU