Getting the best result from your Graphic Corflute

Not all twin-wall plastic sheets are the same. There is only one Corflute®.

Corflute® is a proprietary product manufactured by Corex Australia. Manufacturing products in Australia assists in reducing carbon emissions and energy consumption compared with imported twin-wall plastic alternatives.

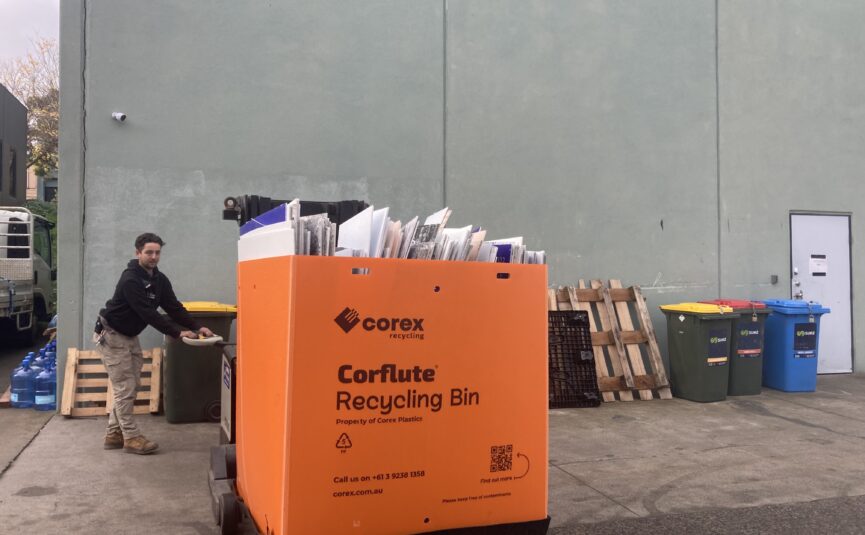

We are different to other suppliers. We are the only twin-wall plastic sheet manufacturer with a closed-loop approach to production. Last year we recycled 500 tonnes* of waste materials returned to us from people using Corflute® in signage and display applications.

We encourage people to bring Corflute® back to Corex Recycling for reuse in new products.

It is in our DNA to reuse and recycle all materials that we produce and we only manufacture materials that can be recycled by Corex Recycling.

Support us to do the best by the environment by choosing Corex Corflute®.

What is the best Corflute® solution for printing?

Are you a graphic solutions provider and new to Corflute®? Or perhaps you have changed your print set up or purchased a new digital printing press and want to ensure optimum speed and quality performance?

Not all Corflute® is the same!

We manufacture Corflute® to order on site here in Dandenong South, Victoria. When you order your media from us, we aim to deliver you a product that is 100% aligned to your production needs to ensure that you can maximise the Corflute® that you print on.

There are many variables that help us to make the best product for you and it starts with understanding your capabilities and quality requirements. How we manufacture Corflute® can affect production efficiency and in turn, cost to you.

Specifying your Corflute®

Partnering with our experienced team at Corex, means that you will receive the best Corflute® for your business.

Here are some of the questions that we run through to help us to manufacture the best Corflute® sheet for your business.

- What is the application? e.g. temporary signage, permanent signage, POS display.

- Are you using the Corflute product indoors or outdoors?

- Are you screen printing or digitally printing?

- What printing presses will you use?

- Are you printing on both sides?

- Are you performing a full-colour print? This helps us to understand if absolute squareness is required and dyne coverage required of the surface.

- Are you trimming the edges or using as is in a fixed frame?

- What is the maximum length variation you can cope with?

- What limitations do you have regarding sheet flatness. Is it critical and why? E.g. Digital press needs sheet can be vacuumed and held flat on bed.

- We usually extrude Corflute® with the “flutes” running in the longest dimension. Please let us know if you would like long flute or short flute.

- Are you adding eyelettes, die or table cutting, creasing, making a product from Corflute etc?

- Would you like to be a Corflute Recycling Program Partner? Exclusive to all printers and distributors of Corflute® or PROMEG® polypropylene. We take your materials back to be reused in our recycled range of sheet and products.

Ask us more? Contact hello@corex.com.au for quick advice.

We make, you use, we recycle.

“Corflute Recycling Partner” branding is exclusive to companies that are part of our full circular economy.

We can offer this program to any user or Corflute® or PROMEG®. Corex Recycling can supply Corpaks® to neatly contain your waste prior to it be sent back to Corex Recycling.

Everything we make is invited to be brought back for recycling and reuse in products for tomorrow. Corex Recycling works alongside the factory that produces Corflute® and PROMEG®.

Learn more about becoming a Corflute® Recycling Program Partner.

Corex Sustainable Plastic Solutions.

Are you looking for high quality graphic sheet with extra sustainability credentials?

We are the exclusive manufacturer of Corflute and Promeg ecorange®; the worlds first 100% carbon neutral plastic sheet. The ecorange® includes products made from recycled and recyclable materials including consumer waste and post-industrial waste.

Corflute ecorange® is our carbon neutral graphic grade offering in the Corflute® family. There are two products in this range; Corflute® eco and Imageboard® eco.

All Corflute® products are designed to be reused again and again. When you have finished with your products, you can return your Corflute and Promeg ecorange® products for reuse within Corex and Megara products. Our materials can be remade infinitely. 100% Australian Made.

Learn more about all our products in the Corex Carbon Neutral ecorange®.

Want to know more about Corflute®?

The plastic sheet with a million uses! Corflute® is an Australian made plastic sheet with endless uses. Corflute® is a proprietary product manufactured by Corex Australia. Corflute is a twin wall profile polypropylene (PP) sheet defined by a series of flutes.

If you would like to know more about what is Corflute® made from, its use in products and industries, its UV and weatherproof credentials, and the different types of Corflute®, please read here for all the answers!

Contact Corex for your graphic Corflute® needs!

Everything that we make is made to order so that can produce things to your exact specifications.

If you are looking to buy Corflute® or other polypropylene sheets and products, the quality selection we produce is what makes us Australia’s leading plastic manufacturer and supplier.

Contact the team at Corex for more information.

About Corex

Corex is a unique Australian closed loop business with polypropylene sheet extrusion, fabrication, and recycling all on one site.

Corex together with Megara, have created a specialist range of products and services including polymer engineering, industrial design, printing, and fabrication so that we can offer a one-stop-shop to bulk handling manufacturers and producers.

Everything that we make is made to order so that can produce things to your exact specifications.

Sign up for industry innovations, special offers and useful information.

"(Required)" indicates required fields